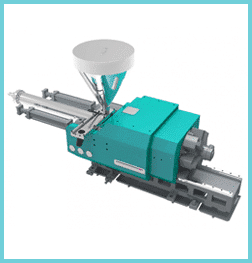

Thin wall injection machine

The thin wall injection molding machine is specifically engineered for the efficient production of thin wall plastic parts used in various industries such as packaging, food and beverage, and consumer goods. This specialized machine combines speed, accuracy and reliability to meet the unique needs of thin wall molding applications.

The thin wall plastic injection machine is designed to optimize production efficiency and quality for thin wall plastic parts. It enables manufacturers to produce lightweight yet strong parts with precision and speed.

Based on many years of experience in the market of hydraulic machines and… to this series of machines, with precision and efficiency

We have reached the top. Our experience and knowledge in this industry guarantee the high efficiency of these machines. Production of quality products

You will experience uniformity with this series of machines. Contact us today to explore how thin wall plastic injection molding machines can help with your specific production needs.

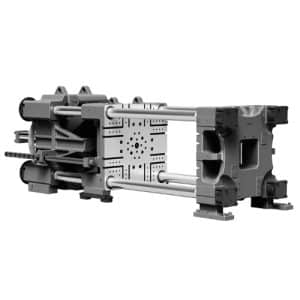

This type of plastic injection machine is designed and engineered to produce thin-walled and sensitive containers

Basic and solid chassis, guaranteeing smooth operation with minimal vibration, at high speed and pressure

is.

- The injection system of servo devices (low consumption) has two jacks, which are installed on the chassis and linear axes. Similar to what is used in high speed devices. The system greatly improves injection accuracy and material loading stability.

- The movement structure of the injection unit is proportional to the cylinders of the carriage. This structure prevents material leakage when injecting at high speed and pressure. The injection and loading part is located on the linear guide, and due to the short distance from the injection center, it creates less torque force, which causes the cylinder to not recoil, during smooth injection and loading.

- The possibility of using multi-stage injection (speed - pressure - position)

- The possibility of using multi-stage material acquisition (speed - pressure - position)

- Using two cylinders for injection to move the spiral forward

- Ability to control cylinder temperature automatically

- The device is equipped with a multi-stage system of material acquisition speed, time and position

- Adjustment of material compression pressure during loading

- Controlling the change of the injection status to the pressure behind the injection

- View the end of the injection on the monitor

- Control of the entire injection stage by an electronic ruler

- The steel material of the nozzle is very resistant and high quality

- Spiral rotation control before material melting

- The injection control system is different in 5 stages

- The system of cleaning the material inside the cylinder of Mardons of size A-B-C-D

- The possibility of using special Mardon cylinders for industrial materials (by metal)

- The possibility of controlling the temperature of the cylinder by PID method

- The cylinder is equipped with a rotating water system in the throat part

- The cylinder is equipped with high temperature ceramic elements

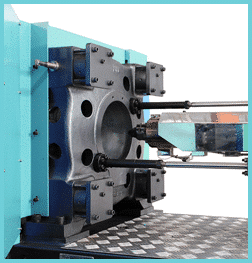

- Multi-stage control of speed, pressure, location, opening and closing of clamp

- The machine is equipped with electrical and hydraulic mechanical protection systems

- The clamp has a system of 5 double joints

- The Pran genas system is designed with a lot of variety according to the type of part

- The clamp includes a central lubrication system, controlled by PLC

- The clip is equipped with a high speed system, in the direction of opening and closing

- The clip is also equipped with a safety lock

- Mold height adjustment, by hydraulic motor command with PLC

- All main rods are equipped with chrome water coating

- Water divider, for mold cooling

- Precise control with and closed clip by electronic ruler

- control of the type of spring (pneumatic _ hydraulic _ shock)

- Using the anti-wear resistance system for the moving plate

- Cast iron clamp plates with the highest accuracy and maximum tensioning, causing the least amount of complexity as well

The lack of difference in size is clamped in the regulatory size

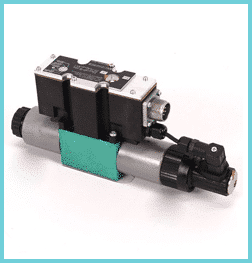

- The technology used in the hydraulic unit has high efficiency, which includes the servo system (low consumption) drive and servo pump, the energy consumption is intelligently controlled based on the pressure and speed factors in the production cycle.

Energy saving, accuracy and speed are the advantages of this technology.

- The special design of hydraulic valves has effectively reduced the pressure drop and increased its efficiency and facilitates oil supply.

- The servo pump system prevents excessive heat production and reduces water consumption to a great extent due to the coolers built into it. Connections and seals of the hydraulic system remove oil pollutants according to environmental standards.

- The possibility of using a robot

- Archiving information of templates and also the possibility of saving in USB

- The possibility of setting technical and advanced information

- Show cylinder temperature

- Accurate use of electronic rulers

- Having a warning system

- The machine's current production conditions are shown on the machine's monitor

- LCD device is equipped with several languages of the world

- By using components and parts in the design and construction of the power system, the command makes it impossible to interfere with any interference during the operation of the device.

- The system is designed in such a way that it provides as many passwords as needed to lock the device

- Protection of data input and operator data by hardware lock

- Real-time production report

- The panel cabinet is sealed with waterproof rubber and prevents water from entering the cabinet

- SSR system is used instead of contactor in all the devices panel

Reviews

There are no reviews yet.