Vertical injection machine

Vertical plastic injection molding machines operate like traditional horizontal machines, however they are designed to work on a vertical axis. This type of plastic injection machines in hydraulic, electric and hybrid types is designed to meet a wide range of customer needs. Vertical injection molding machines require very little environmental space due to the type of machine orientation and different design than conventional injection machines.

Vertical plastic injection machines, also known as vertical injection molding machines, are a type of injection molding machine in which the injection unit and the clamping unit are aligned vertically. This configuration is different from horizontal injection machines where the injection unit and clamping unit are placed horizontally.

In addition to the mentioned inherent properties, vertical injection machines are designed in such a way that they are suitable for the production of insert parts.

For example: the height of their table is enough for the user to easily access it and insert the insert parts into the mold.

Also, some facilities such as revolving and sliding tables have simplified this work even more.

Among the applications of the vertical plastic injection machine can be the production of electrical components, car parts, LED lamp shell or body,

He mentioned all kinds of wires and sockets, medical equipment, all kinds of parts with inserts or implants, etc.

In addition, most machine manufacturers produce vertical plastic injection machines in lower tonnages than horizontal machines.

which naturally have a lower price. Many manufacturers need a machine with low tonnage to produce plastic parts.

Therefore, buying a horizontal injection machine imposes an additional cost on them. Clamping force in horizontal plastic injection machines

The ones available in the Iranian market are usually from 80 tons and up, while vertical injection machines with a clamping force of 20 tons are easily available.

The low price of vertical injection machines is especially attractive for entrepreneurs who are just about to enter the plastic industry.

Another advantage of the vertical plastic injection machine is that it occupies little space, and in this sense, it is suitable for small workshops.

It is a very good product. Due to their low price and small size, these devices meet the needs of people in some cases

who are looking for a home plastic injection machine.

Takes up less space: Vertical injection molding machines are smaller in size compared to horizontal machines, making them ideal for facilities with limited space. They can be installed in tight production areas or integrated into existing production lines without the need for extensive layout modifications. Versatile mold design: Vertical plastic injection machines incorporate molds that open and close vertically, which can be useful for specific part and molding processes. They are suitable for over molding, insert molding, and molding parts with complex shapes or multiple inserts. Easier Access: Vertical machines are easier to access and maintain due to the upward orientation of the mold and injection unit. Maintenance, mold changing and troubleshooting can be done more easily and efficiently compared to horizontal machines. Overmolding Capabilities: Vertical plastic injection machines excel in overmolding applications where one material is molded onto another substrate, such as encapsulating electronic components. Vertical orientation facilitates precise molding of parts and ensures proper material bonding and dimensional accuracy. Minimize material waste: Vertical plastic injection molding machines can minimize material waste by precisely controlling shot size and material flow during injection. This can lead to lower material consumption and cost savings, especially for small to medium sized parts. Advanced Automation Options: Vertical injection molding machines can be easily integrated with automation systems for parts handling, assembly and quality control. Automated processes improve overall production efficiency, reduce labor costs and ensure part quality. Specialized Applications: Vertical machines are preferred for specific applications in industries such as automotive, medical equipment, electronics, and consumer goods. They are versatile tools for molding components with different material properties, colors and surface coatings.

Application of the device: Vertical molding is suitable for iron, aluminum, brass/bronze and steel castings with mold sizes from 400 x 500mm to 1200 x 1050mm.

This process is widely used in the automotive industry to produce high volumes of parts such as brake calipers, brake discs and exhaust manifolds.

Many other applications include household frying pans and pipe fittings to fire hydrants, etc.

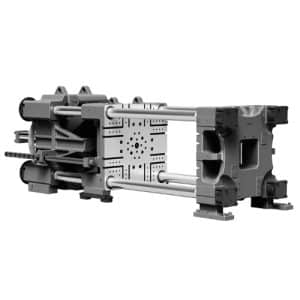

- fixed table

- Double sided sliding table

- Turntable

Fixed table vertical plastic injection machine:

- The fixed part of the mold is closed on the fixed plate of these devices and as its name suggests,

It is fixed and does not have the ability to move transversely. Fixed tables for the production of parts that do not have a high production rate

They are very suitable. Also, vertical injection machines equipped with a fixed table are cheaper than other types of machines.

Among the applications of devices equipped with this table, we can mention the production of electrical equipment, wire heads and socket heads.

One-way sliding table vertical plastic injection machine:

On the fixed plate of the clamp of these devices, a table with the ability to move transversely is installed, which allows this possibility.

that the fixed part of the mold (which depending on the type of mold may be the cavity or core of the mold) moves towards the operator when the clamp is opened

And by moving out from under the moving screen, it provides more space for the operator to remove with more freedom of action and safety.

parts or inserts. This type of table is used in parts that are difficult to insert, such as switches and sockets.

Automotive parts and electrical equipment.

Two-way sliding table vertical plastic injection machine:

The philosophy of equipping the vertical injection machine to the double-sided sliding table is the same as the one-sided sliding table in order to facilitate insertion.

with the difference that the use of a double-sided table makes it possible to while the clamp of the device is in the locked state,

From one side, the fixed part of the mold is out of the clamp and is available to the operator to remove the produced parts and insert them.

For this purpose, it is necessary to make the fixed part of the mold in two or more numbers. This type of table is used to produce parts that have a cooling time

Or the insertion time in them is high, it is very suitable. The production rate of parts using machines equipped with two-way sliding table is very high.

Naturally, these devices have a higher price than the previous two types. Machines equipped with double-sided sliding tables are usually used to produce electrical components.

Medical equipment and electrical equipment are used.

Vertical rotary table plastic injection machine:

The rotary table is used like sliding tables to facilitate part removal and insertion. In addition, due to the possibility of installing several mandrels

(or the fixed part of the mold) on a machine, and the ability to insert and remove parts during the production cycle, the production rate is greatly increased.

Also, these devices are very safe due to the large distance between the operator's position and the clamp of the device. Using plastic injection machines

Amoud equipped with a rotary table can produce many parts with complex production methods, such as LED lamp shells, medical equipment, and automobile parts on a mass scale.

Reviews

There are no reviews yet.